Shotcrete Equipment

Maximize efficiency with Shotcrete equipment from Multicrete

Having the right Shotcrete equipment on the job makes all the difference. Whether you’re spraying Shotcrete in subterranean excavations, mines, or large civil construction projects, our Shotcrete equipment allows for flexible and efficient application while also reducing construction time. Find the right Shotcrete equipment for your project from our vast selection.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Multicrete Raise Robot®

The Multicrete Raise Robot® Robotic Raise Applicator is a remotely controlled robotic assembly for the spraying of shotcrete; used in shafts and raises of subterranean excavations. This robotic unit is designed for use in mines and on large civil construction projects.

The standard Multicrete Raise Robot® is designed for use in raises a minimum of 1.5 meters diameter up to a maximum of 10 meters diameter. Hydraulic retractable arms stabilize the The Multicrete Raise Robot® and allow for undulations along the interior surface of the raise.

Operating Principle

The Multicrete Raise Robot® is lowered by means of a heavy-duty incremental winching system. This system allows for variable speeds from 5 cm/minute up to 6 m / minute.

During its descent, the Multicrete Raise Robot® washes (hydro-blasts) the interior surfaces, as wel as videotapes the entire raise.

On its return, the unit commences spraying shotcrete in a uniform single pass. The electric motor on the spray head allows for 360° non-stop rotation.

Application of Shotcrete

The Multicrete Raise Robot® is used in conjunction with the Aliva electric powered shotcrete machine mounted on a Multicrete Integral Predampener.

Predampened material is conveyed through 50-65 mm. diameter heavy duty hose for the remote application of shotcrete via the Multicrete Raise Robot®.

At surface level, technicians monitor the progress of the Multicrete Raise Robot® via video display. This allows for the rate of application to be modified without personnel entering the raise.

Shipment

All the required equipment, spares and accessories can be compacted for shipment into a 20’ sea container. The Multicrete Raise Robot® collapses to just 1.8 meters in height, 2.7 meters in length and 1.8 meters in width for ease of transport.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Multicrete HW10H Hybrid-Wet™ Shotcrete Carrier

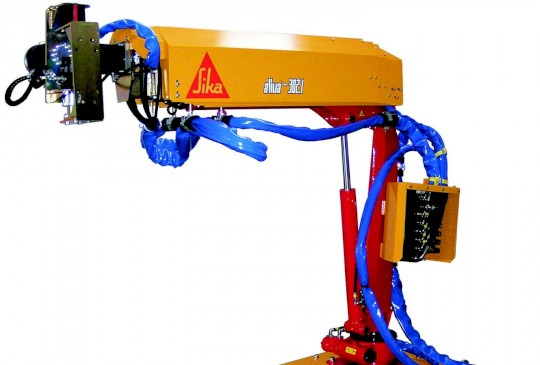

Aliva® Shotcrete Machine, AL-302 Spray Arm on Carrier

A shotcrete carrier includes a dry mix hopper, a wet mix shotcrete spraying machine, and a mixing auger for wetting the dry mix as it is conveyed from the dry mix hopper to the shotcrete spraying machine on a common mobile frame.

The shotcrete spraying machine comprises an inlet hopper receiving the wet mix shotcrete from the mixing auger, and a rotor with chambers rotatable from a loading position in communication with the inlet hopper and a discharging position in communication with a pneumatic conveying line. The pneumatic conveying line conveys the wet mix shotcrete to a nozzle commonly supported on the mobile frame.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Aliva® Shotcrete Machine, AL-302 Spray Arm on Carrier

A shotcrete carrier which includes a state of the art Aliva 257 wet/dry shotcrete machine on the rear, an Aliva® 302 wet mix shotcrete spraying arm on the front, enhanced hydraulics, self-contained liquid accelerator storage & pumping system all on a Multicrete™ Huron 4 Shotcrete Application Carrier chassis. A very compact, maneuverable, tough unit designed to get the job done!

- Huron 4 Specifications

- ALIVA® 302 Spray Boom Specifications

- ALIVA® Shotcrete Machine Specifications

Huron 4 Specifications

TRANSMIXER TRUCK:

Chassis: Monoblock. Heavy duty type.

Engine: Diesel CUMMINGS type QSB 4.5 (TIER lll-COM lll),4 cylinders, turbo intercooler. Liquid cooling. Power DIN 116kW (155HP) to 2,200 r.p.m. It is designed to work at 4700 MASL.

Axles: Monolithic with epicycloids reducer. Dynamic loading capacity per axle 8000 kg. Steering type front axle with oscillating assembly. Fixed rear axle.

Transmission: Hydrostatic type with automatic regulation. Axial pistons pump of variable flow applied directly to diesel engine. Hydraulic motor at axial pistons mounted on reducer cap

Steering: Hydraulic on front axle.

Brakes: Internal discs oil bathed on front wheels. Hydraulic activate in two independent circuits. Parking brakes on transmission with hand lever control.

Drum

| Concrete output capacity | 4m3 |

| Direct unloading height | 1,465 mm |

| Unloading height | 1,100 mm |

Hydraulic rotation of drum for loading-mixing and unloading is effect by electric speed regulation of rpm.

Water System: Hydraulic operated self-priming water pump. The water is supplied from an external source, taken directly to the drum, to the tank or the washing hose. It can also be taken from the truck mixer tank to the drum or the washing hose. High pressure pump for cleaning purposes. Litre counter.

Max Slope

| Fully Loaded | 30% (SAE normative) |

Speed

| 1st | 0-8 km/hr (for working) |

| 2nd | 0-20 km/hr (for movement) |

Steering Radius

| Internal | 4,150 mm |

| External | 7,800 mm |

Electrical: 12 V battery 180 Ah, 650 A

Tires: 10’00R20 16PR

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Pre-dampener and Aliva Dry Mix Shotcrete Machine Combination

This easily transported Multicrete™ Integral Shotcrete Unit consists of an Aliva dry mix shotcrete machine and a Multicrete™ Predampener, mounted together on a common frame. Preparation includes connecting the “Bull Hose” from the air supply to the inlet on the predampener frame. The water line is then connected to the spray nozzle assembly located on the mix auger. Finally, the material delivery hose can be attached to the outlet chamber assembly of the Aliva pot and shotcreting can proceed.

Purpose

The Hopper on the Predampener allows for a continuous feed of pre-blended dry mix shotcrete – even during bulk bag changes. The feed auger located under the hopper then feeds a mix auger where water is added to suppress dust and to allow the nozzleman to easily regulate the water at the nozzle.

Power Options

Electric

- 5 hp helical snuggler gear motor to mix auger.

- 3 hp variable speed motor to cross feed auger.

- Centrally mounted electrical control panels.

Pneumatic

- 2” filter/regulator/lubricator system.

- 12 hp vane motor, helical worm gear reducer to mix auger.

- 7 hp vane motor, helical shaft mount reducer to feed auger.

Please refer to the TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Fully extended Multicrete™ Auto Parallel Travel System demonstrating vertical/horizontal reach.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Forklift with AL-302 Spray Arm

Multicrete Systems Inc. announces the Multicrete™ MSU 420/302, a complete mobile shotcrete unit complete with front forks and a shotcrete boom with a reach of over 18 feet!

Carrier

Make & Model Kubota, R420 D1503-T-RP-1

Type Liquid cooled, 3 cylinder

Turbo Diesel

Horse Power……………………..43.0 @ 2,600 rpm

Operating Weight………7,275 lbs (3,300 kg)

Displacement……………..91.4 cu. In. (1,497 cc)

Turbo Charger……………… Yes

E-TVCS…………………………. Yes – Low Emissions

Overall Width……………..4’-11.8”

Wheel Base…………………5’-9.9”

Ground Clearance………11.3”

Tread………………………….3’-10.5”

Angle of Articulation….40

Frame Oscillation

FORKLIFT………………………8

Maximum Lift……………..10’

Forks (folding)……………. 2-1/2” X 5”X40”

Capacity…………………….5500 lbs

Free Lift…………… Full

Shotcrete Boom

Maximum Height……………….21’

Maximum Length………………19’

Minimum Length……………….8’

Angle of Rotation………………110

Spraying Angle………………….240

Remote Control……………….. Hydraulic

Hydraulic Aggregate……………14 L/min

Electric Drive…………………..5.5 kW

Or Air Drive………………………7 kW

Diesel Engine……………………. Via carrier.

Please refer to the TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The AL-267 is a multi-functional machine for wet- and dry application of sprayed concrete in the thin stream method. The modular construction allows the right type for all requirements. With an output capacity of 4-21m3/h the range of applications covers: Excavation-protection, rock stabilization, slope protection, swimming pool construction, hydropower projects, tunnelling, mining etc.! Easy handling, flexibility and functionality are unique for the AL-267.

Design and Safety

Modern designed hoods and covers of all moving components with integrated emergency Stop to guarantee the highest level of safety for the operator. Danger of accidents is reduced to the absolute minimum.

Depending on the Type of AL-267 all components as Dosing Unit for accelerators, automatic central lubrication system and regulation of the rotor-speed are compact integrated under the covers of the machine.

Opening the covers stops the rotor from turning and shuts the airflow automatic.

Pneumatic fine-tuning of the 3-Pt. clamping device (longer hose length, more pressure on the clamping device). Both rotors made of aluminium. (15.5 I and 26.5 I). Easy handling and cleaning of the components and exhaust. Unique developed sealing system from Aliva made of special steel on steel with vulcolanic dust sealing rotor plates. Very low wear of up to 1500 m3/plate guarantee economic operation, low wear and no more interruption for changing plates.

Please refer to the TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The telescope spraying arm AL-302.1 has been designed specially for mines, small galleries and excavations. Owing to its simple and rigid construction it is most suitable for mounting onto different carriers.

Uses:

- For mining and small tunnels

- Modular concept

- Air, electric driven

- Simple mounting onto carriers

Please refer to TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Dry and Wet Shotcrete

The AL-257 is the universal machine for the application of dry- and wet shotcrete in the thin-stream method. The new and very compact design of the machine impresses through its dimensions, weight and performance. With just 750 kg and dimensions as little as a small dry shotcrete machine, the AL-257 fits on every job site and is easy to install and operate. With its unbelievable output capacity range from 0.7– 9.6 m3/h (with 3 rotor sizes) the machine works on small concrete renovation work as efficient as on big slope protection or in mines. Less maintenance and wear cost makes it the ideal shotcrete machine for all applications.

Fields of application:

- Wet- and dry shotcrete application

- Concrete renovation

- Joint-fillings

- Swimming ponds, swimming pools

- Slope protection, rock consolidation

- Canal-renovation (sewage)

- Mining and tunnel applications

With the newly developed, universal AL-257, dry- and wet shotcrete are equally possible. No changing on the machine from dry to wet shotcrete has to be performed.

For changing from wet to dry shotcrete, the machine has to be cleaned and dried up. The integrated exhaust system and a newly designed hopper allow a high filling degree of the rotor chambers, which leads to low pulsation and less rebound.

The AL-257 is equipped with a fully automatic lubrication system for the rotor-discs. The rotor-speed is adjusted with a frequency converter and therefore, can be adjusted to every specific need on the job.

The machine has an emergency button which stops the turning of the rotor and closes the main valve of the air supply.

With a weight of just 750 kg and compact measurements, the AL- 257 fits on every site, is easy to handle around and adjusts itself to every application. With a huge spectrum of conveying capacity from 0.7–9.6 m3/h, there is no work which could not be conducted economically. Is it for thin layer concrete renovation with the 2.5 l rotor up to slope protection of an excavation with the 12 l rotor, with the AL-257 one has always the right equipment.

The machine is equipped with rotors made of high tec aluminium and is operating with steel- on steelwear- and rotor plates. Experience has shown up to 10 times less wear on the steel plates, depending on material, output capacity, hose diameter and compressed air supply! This again leads to less standstill time and wear-cost and therefore to more economical spraying operation hand.

Please refer to TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva®-252 is a sturdily constructed two-axle concrete spraying machine for the processing of dry mix.

Uses

The machine can be used thanks to its compact design and mobility where space is at a premium e.g. in mines and galleries. Other potential applications are slope and hillside protection, lining of water tanks and swimming pools, guniting for single and double shell tunnel construction, backfilling of tubbings.

The Aliva®-252 is available in the following versions:

- Basic: Electric drive, combined with BASIC-Dosing unit (not synchronized)

- Air: With air drive, combined with BASIC-Dosing unit (not synchronized)

Please refer to TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva-237 is a sturdy concrete spraying machine for wet and dry spraying process.

Uses Thanks to its variable output, the Aliva-237 can be used for small jobs, such as joint filling, as well as for extensive slope consolidation work.

The Aliva-237 is available in the following versions:

- Standard: Electric drive, single speed

- Top: Electric drive, with FC for variable rotor speed

- Air: With air drive, variable rotor speed

Please refer to TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva®-246 is a sturdy concrete spraying machine for the dry spraying process.

USES

Thanks to its variable output, the Aliva-246 can be used as well for small jobs, such as joint filling, as well for extensive slope consolidation work.

The Aliva-246.5 is available in the following versions:

- Basic: Electric drive, combined with BASIC-Dosing unit (not synchronized)

- Extended: Electric drive, combined with EXTENDED-Dosing unit (not synchronized)

- Air: With air drive, combined with BASIC-Dosing unit (not synchronized)

Please refer to TDS for detailed technical information.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Compact Wet-Process Shotcrete / Concrete / Grout Pump

The extremely compact size of the Mine 30 pump makes it ideal for underground applications or any application with limited space (96″x46.5″x64.7″).

- The Mine 30 is suitable for cross mounting on a truck or other carrier.

- Fork channels on the side and end also come standard.

- The Mine 30 can be powered by an electric, diesel, or air motor.

The simple design of the Mine 30 makes it easy to trouble-shoot and service. It provides strong performance, extreme dependability and long life of all wear parts.

Standard Features

- Heavy-duty “S” Valve

- “Open-Loop” hydraulic system and a variable displacement hydraulic pump.

- Adjustable shifting force valve

- Chromed concrete cylinders for long service life

- High-strength frame design (sturdiest frame in industry)

- Highest commonality of hydraulic Hoses

- Shotcrete

- Concrete Pumping

- Grouting

- Backfill

- Mine & Tunnel Support

- Flowable fill

- Specialty Materials

Additional Features

- Weatherproof NEMA 4 control panel

- Reversibility at any point in the stroke

- High capacity hydraulic oil cooler

- Fully-variable volume output

- Automatic pressure release at shutdown

- Forged steel pistons with urethane cups

- Hard chromed concrete cylinders

- Hour meter/tachometer

- Emergency stop button

- 5-function cable remote control

- Dual hydraulic circuit

Optional Features

- Radio remote control (On/Off/ Reverse/E-stop/Horn-reset / Engine RPM)

- Hopper agitator

- Vibrator for hopper screen

- Chemical additive pump

- Stroke counter

- Lifting-eyes

- Hydraulically driven water washout pump

Please refer to TDS for additional features.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

3000 lb Heavy-Duty Electric/Hydraulic Power Pan Mixer

- 3,000 lb concrete / shotcrete batch capacity (subject to density of material)

- Variable Speed Mixer Blade Rotation – 59 RPM maximum

- Hydraulic Motor Drive, Torque 13762 Nm (Variable Displacement Hydraulic Piston Pump (displacement 71cc)

- Twin Discharge Doors (for the option of running two pumps at once)

- NEMA 4 Weatherproof Control Panel on Operator Platform

- Power On-Off, Mixer Stop-Start, E-Stop, Horn-Reset, Mixer RPM Control, Primary Discharge Open-Close, CleanOut

- Discharge Open-Close, CleanOut Tilt Up-Down, Hydraulic pressure gage and Amp meter

- Work Platform with Control Box and Safety Railing

- Quick Disconnects (Hydraulic, Electrical) for ease of set-up and clean-up

- ForkLift Tubes and Lifting Eye Kit On Mixer for Easy Lifting and Transport

- Optional Stainless Steel Water Tank for Precise Water Measurement (+ optional flow meter)

- Optional Pressure Washer (3 gpm flow, 2000 psi, hydraulic)

Dimensions: Width: 86” (7 ft, 2 inches)

Height Minimum: 102” (8 ft, 6 inches) (when collapsed for transport (bag splitter can be removed to reduce height 22″ further)

Height Maximum: 154” (12 ft, 11 inches) (for operation at max height)

Minimum clearance under discharge door: 67″ (1701mm)

Maximum clearance under discharge door: 99” (2515mm)

Weights: Mixer: 7300 lb (3312kg), PowerPack 2300 lb (1044kg)(estimates)

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Forklift with AL-302A Spray Arm

Multicrete Systems Inc. announces the Multicrete™ MSU R520S, a complete mobile shotcrete unit complete with front forks and a shotcrete boom with a spray capability of over 26 feet.

Carrier

Make & Model Kubota, R520S C/W AL302A & 6000LB Fork Mast D1503-T-RP-1 Type Liquid cooled, 3 cylinder Turbo Diesel

Horse Power: 43.9 @ 2,600 rpm

Operating Weight: 7,275 lbs (3,300 kg)

Displacement: 134.1 cu. In.

Turbo Charger: No

E-TVCS: Yes

Overall Width: 69.3”

Wheel Base: 76.8”

Ground Clearance: 12.8”

Tread: 53.5”

Angle of Articulation: 40

Frame Oscillation:8”

FORKLIFT: 8

Maximum Lift: 10’

Forks (folding): 2-1/2” X 5”X40”

Capacity: 5500 lbs

Free Lift: Full

SHOTCRETE BOOM

Maximum Height: 26’

Maximum Length: 24’

Minimum Length: 8’

Angle of Rotation: 110

Spraying Angle: 240

Remote Control: Hydraulic

Hydraulic Aggregate: 14 L/min

Electric Drive: 5.5 kW

Or Air Drive: 7 kW

Diesel Engine: Via carrier