Menu

Having the proper accessories when you’re working on a site with shotcrete makes all the difference. Whether you’re working with mesh forms or lattice girders, our Shotcrete accessories allow for efficient application while also reducing construction time. Find the right Shotcrete accessories for your project here.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Excellent for lifting & handling bulk bags up to 6000lbs

The Bulk Bag Lifting Cross can be used in conjunction with other machinery to lift and handle bulk bags up to a capacity of 6000 lbs.

Designed with ease of use and Safety in mind this apparatus can take the punishment making your worksite more productive.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

We stock a complete line of nozzles, bodies, hoses, clamps, and more to fill your Shotcreting needs. We also stock a complete lineup of wear plates, rotors, and other parts for most Aliva equipment.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Designed to be integrated into the shotcrete shell, resilient to close proximity blasting.

Shotcrete Mesh Panels are constructed with black or galvanized mesh and burlap cloth. Stiffeners are incorporated for three-dimensionable stability. The panels can be various sizes depending on application. They are lightweight and can be cut-to-shape with small bolt-cutters. When Shotcrete is applied to the panels, the result is a durable wall, which is resilient to close proximity blasting.

Mesh: 2″ x 2″. Panel: 8′ x 4′.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Lattice Girders were developed for the special demands of mining and tunnel construction.

Contrary to rolled sections, regardless of shape, the Lattice Girders are completely integrated into the shotcrete shell.

Porous zones, respectively spray shadows are avoided.

Settling of the surrounding ground is reduced and the water tightness of the shot-crete shell is improved significantly.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Multicrete MULTI-Drain® strip drain is a prefabricated, high-flow drainage system that offers better draw down of water than pipe while costing around 60% less to install.

MULTI-Drain® strip drain consists of a formed polymeric core surrounded by a geotextile filter fabric. The fabric allows water to pass into the core while restraining other particles which might clog the core. The core allows water to flow to designed rain exits. MULTI-Drain® strip drain is 1” thick by 4” – 36” wide and is available in 100’ and 500’ long rolls.

The multichannel structure of the formed polymeric core provides significantly increased water flow. The tough non-woven, needle-punched geotextile filter fabric covering prevents core clogging while allowing water entry through every inch of its surface.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

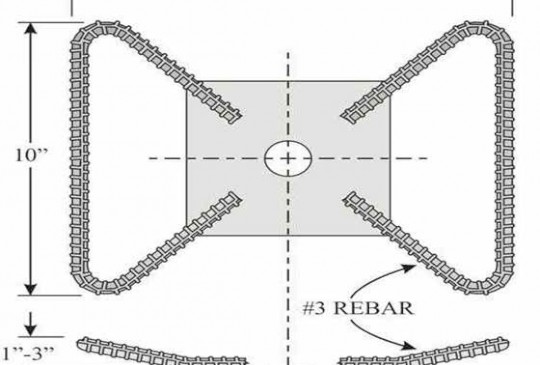

A shotcrete mesh reinforcing solution.

Shotcrete butterfly plate washers are available in a range of sizes.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The fully automatic lubrication system consists of an air filter, air regulator with gauge, an airline lubricator, a timer switch, a 3-way solenoid pump, and injectors.

Controls can be electrical, mechanical or manual.

The electrical timer switch opens a three-way solenoid valve, permitting air to flow to the pump forcing the air piston forward and lubricant through supply line to the injectors. When the valve closes, air exhausts back through the valve, and the spring in the pump returns to the air piston, completing the lubrication cycle.

Frequency of the cycle can be set as desired.

2500 Ferrier St.

Winnipeg, MB

R2V 4P6

204-262-5900

EMAIL US

All Rights Reserved – Multicrete Group Inc. | Privacy Policy & Terms of Service | Strategy & Design by Loomo